Daniel's Rig (aging flooring)

When it comes to aging materials, we have all kinds of customers, but often they fall into two categories: Those who want a down and dirty solution for a one time project, and those who want a permanent rig that they can use daily, for years. Daniel definitely built something worth while and went the extra mile to do everything right. You don't need to take the extraordinary steps he did, but there is nothing wrong with doing so either.

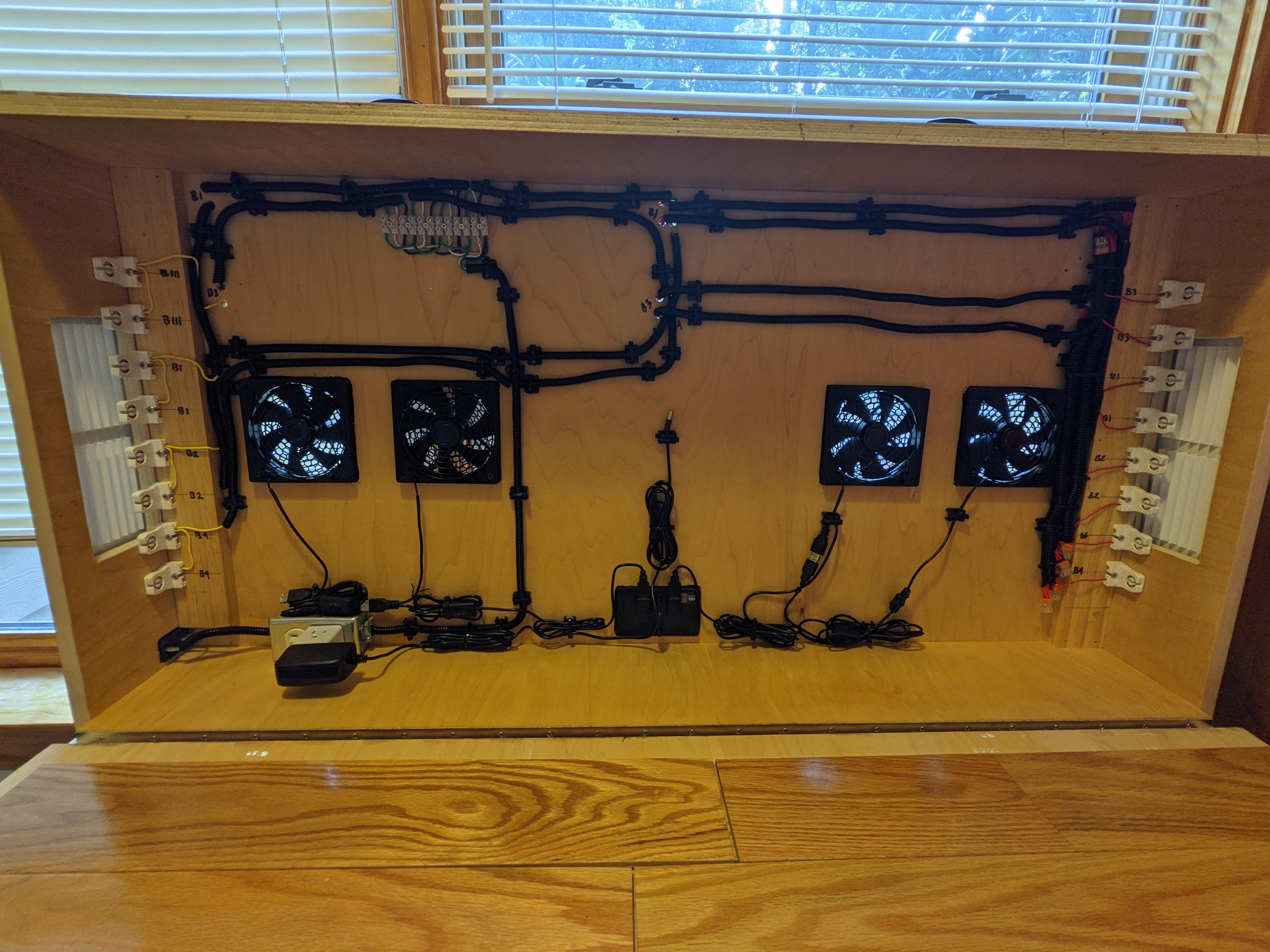

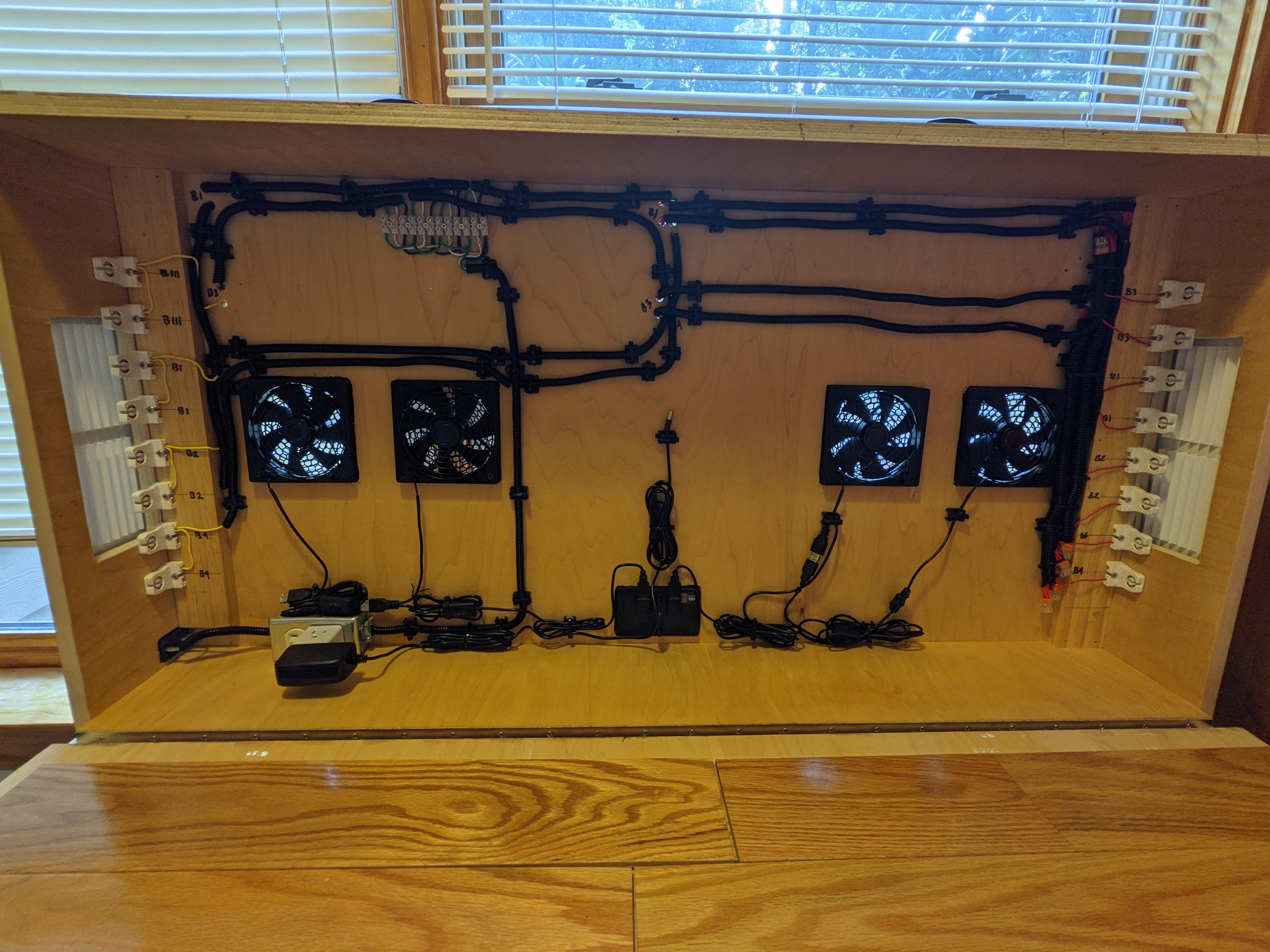

Daniel built this rig specifically for aging wood flooring, before it is installed. This is actually easier because you are dealing with many small boards that can be brought to the again rig, instead of curing after you install, where you have to bring the aging rig to the floor and mask off. Here is what Daniel used:

- Two VHO aging/curing kits, meaning

- Eight Solacure 4 foot SG-1-40 FR40T12 bulbs

- Four Workhorse 8 high output ballasts (two bulbs per ballast, 80w per bulb, 640w total)

- Four 4" fans (not included in the kits), Leviton lamp holders, lots of tubing and plywood.

For simple applications with one rig, a temperature monitoring system isn't always required, but honestly, it is worth the investment. The lamps will always put out the highest amount of UV per watt when the air around them is between 90F and 100F (32C to 38C). Once the temperature of the air exceeds 110F (43C), the output will go down and you start getting reduced lamp life. If the temperature is below 70F (21C), then the output starts to dramatically drop, although this won't affect lamp life. In short, 70F (21C) and 100F (38C) is the operating range, with 90F to 100F (32C to 38C) being the optimal range. Of course, it is common for them to be below this when they first start, and they will heat up the chamber. You just won't know how much unless you use *something* to monitor it.

Daniel is matching old wood with new wood, a common task. How long this takes greatly varies and mainly depends on whether the wood is finished or not, and if it is, with what kind of finish. To a lesser degree, it also matters how "aged" the old wood is, ie: how dark it is compared to when it was new. We tell our customers that 3 to 7 days is the typical range. Daniel reported back that it took 48 to 60 hours, which is right in the middle of the range and for most people, very workable. This is due in part because he is running eight lamps in a fairly tight configuration, rather than four.

This doesn't necessarily cut the time in half (close to 50%) because wood can only age so fast. Doubling again, for instance, to 16 lamps might knock 12 to 24 hours off but that is it. To properly age wood, you need more than UV, you need UV and a little time.

Here are the images he sent, which are very high resolution. Just click on any image to pop open a new window with it at full size.

This was put together Sept 2021.

Daniel built this rig specifically for aging wood flooring, before it is installed. This is actually easier because you are dealing with many small boards that can be brought to the again rig, instead of curing after you install, where you have to bring the aging rig to the floor and mask off. Here is what Daniel used:

- Two VHO aging/curing kits, meaning

- Eight Solacure 4 foot SG-1-40 FR40T12 bulbs

- Four Workhorse 8 high output ballasts (two bulbs per ballast, 80w per bulb, 640w total)

- Four 4" fans (not included in the kits), Leviton lamp holders, lots of tubing and plywood.

For simple applications with one rig, a temperature monitoring system isn't always required, but honestly, it is worth the investment. The lamps will always put out the highest amount of UV per watt when the air around them is between 90F and 100F (32C to 38C). Once the temperature of the air exceeds 110F (43C), the output will go down and you start getting reduced lamp life. If the temperature is below 70F (21C), then the output starts to dramatically drop, although this won't affect lamp life. In short, 70F (21C) and 100F (38C) is the operating range, with 90F to 100F (32C to 38C) being the optimal range. Of course, it is common for them to be below this when they first start, and they will heat up the chamber. You just won't know how much unless you use *something* to monitor it.

Daniel is matching old wood with new wood, a common task. How long this takes greatly varies and mainly depends on whether the wood is finished or not, and if it is, with what kind of finish. To a lesser degree, it also matters how "aged" the old wood is, ie: how dark it is compared to when it was new. We tell our customers that 3 to 7 days is the typical range. Daniel reported back that it took 48 to 60 hours, which is right in the middle of the range and for most people, very workable. This is due in part because he is running eight lamps in a fairly tight configuration, rather than four.

This doesn't necessarily cut the time in half (close to 50%) because wood can only age so fast. Doubling again, for instance, to 16 lamps might knock 12 to 24 hours off but that is it. To properly age wood, you need more than UV, you need UV and a little time.

Here are the images he sent, which are very high resolution. Just click on any image to pop open a new window with it at full size.

This was put together Sept 2021.

| Solacure Means Quality Solacure ultraviolet lamps aren't just good, we guarantee they are the best or we will give you your money back. Our patented glass is more transparent to UVA and UVB. Our custom cathode/anode sets lets you run 2 to 3 times more power than a standard lamp in the same size. All of our lamps have built in reflectors. We have a lamp for every need. We stand behind everything we sell and guarantee each will perform exactly to specification, or we will replace them. We don't want your business this week, we want it every week, and we are willing to earn it. There really is a difference in quality when it comes to ultraviolet bulbs, and Solacure tops the list. Order online, over the phone, or call us if you need a custom UV lamp made, with fairly low minimums (around 2000 pieces). We can make it happen. Buy with confidence: We like what we do, and we've been doing it for over 30 years. |

Got a question? The best way is usually to email us at sales@solacure.com. |